It removes cations, anions, and particular harm ful materials from a solution,

using ion exchan ge resin. It is used for softening water, removi ng iron and manganese,

and making pure water. With RO and MF system added, it can make ultra-pure water.

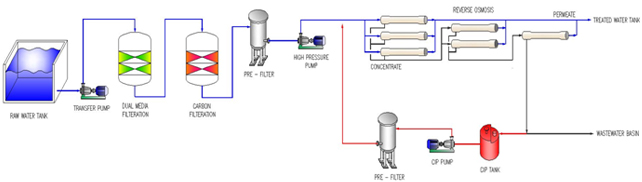

Reverse osmosis(RO) is using a semipermeable membrane and

it is the most economic and effective system that can remove 99%

of impurities in water by passing through only water molecules as

pressed high concentration of the solution.

All dissolved inorganic matter, organic matter in water and all insoluble

substances including the particle microorganism are removable.

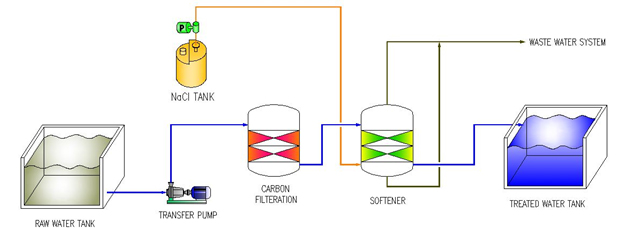

SOFTENER facility is a disposal equipment utilizing

ion-exchange reaction after passing calcium, magnesium

and etc, hardness components, containing in the raw

water, through cation exchange resin layer.

If resin filter a quantity of soft water, exchange-competent decline.

At this moment, 5~10% of NaCl is used as regenerant and resin drives again.

An pure device of ion exchange resin eliminates cation and anion of raw water

with combination cation-exchange resin and anion-exchange resin.

Cation-exchange resin and anion-exchange resin are charged by each separate

independent tower. And then there are multiphase tower method blearing raw

water by connecting the tower and mixed-bed tower method charged by one of

the tower by mixing cation-exchange resin and Anion-exchange resin uniformly.

UV light energy has short waves and it has the unique function of sterilizing germs by contacting every type of microorganism at a wavelength of 2854mm.

The UV light energy emitted from a low-pressure mercury UV sterilization lamp has a high output power for sterilization. It can kill 99.7% of all types of germs and fungus. As the spectrum penetrates transparent material such as water, air or oil, the invisible rays of UV light kill all the germs.

ron or manganese causes colorization or metallic odor in the water and it can hinder various industrial processes. Removal or such materials can be most effectively done through a contact oxidation filtering method. Using filtering materials (Filox, Ferox, Birm, Metal-ease, Manganese green sand), we can successfully filter them out. In this case, the filtering material promotes a catalyst effect and use of additional oxidants such as air or chloride will help you to process them more effectively.

The micro filtration system has very similar use to the filtration method for using media from the standpoint of the general concept of filtration. However, in actual application, it has some unique structural differences. When the pollutants contained in the supplied water are stuck or absorbed in the media layer, the device using media discharges them to the outside using a backwash process in order to maintain its original functions. On the other hand, the micro filtration system utilizes the cartridge type of filter that is manufactured from high porosity chemical textile and located inside the vessel. If the amount of pollutants stuck in the filter is saturated as the supplied water moves from the outer area of the filter to the inner area of the filter, the filer should be replaced.

The ozone is second and as the allotrope of the oxygen element sign O ₃, molecular weight 48, specific gravity 1.7 in various possibility control as the light blue gas which is, the fluorine (F) with strong oxidizing power to disjoint the organic matter sterilizes, decolorization and seizure and removes BOD and COD is applied. The ozone from the inside which will bite the oxygen the solubility creates after autolysis bigger OH where. (Hydroxyl Radicals) reacts with the organic matter quickly and after reacting smell does not leave not to be does not leave a chemical property the mortar does not do a color and the secondary high seas.

micro filtration system with the method which uses the filter medium (MEDIA) are general and when 'filtration' seeing from concept, the use is similar, but there is to actual application and there is structure state a difference of the somewhat that. The system which uses MEDIA the feed water passes MEDIA layer and the contaminants which contain are detained in MEDIA layer and when they are absorbed, backflush process leads and the contaminant which is detained with exhaust Sikkim the function reduction is a method which maintains at the outside, micro filtration system insertion affixes CARTRIDGE TYPE FILTER where is manufactured with chemical fiber etc. of porosity within VESSEL and the contaminant detainment is filtrated from the process where when the feed water from FILTER outsides passes a fiber layer with inside and the detainment quantity becomes saturated state and exchanges FIILTER and is a method which uses.

The reverse osmosis effect using the semi-permeable membrane existing

in nature allows you to remove about 99% of mineral materials, ionized

inorganic materials, various impurities, bacteria and germs, SS contained

in the polluted underground water, rusts and iron in the faucet water and 2-D

synthetic materials of some water supplies affected by industrial waste water

(300 molecule weight or greater). It is used as a pre-process for the ultra pure

water for semiconductors and it is used for a wide range of water treatment facilities

including the sea water treatment facility.

This device manufactures pure water by passing the supplied water through the

strong acid cation exchange resin and the strong alkaline anion exchange resin

inside a single tower. If the supplied water contains a large amount of salt, it very

effective in performing pre-processing with the strong acid cation exchange resin

and the weak alkaline anion exchange resin. Compared to the two-bed ion exchange

system, it can maintain more stable water quality depending on the quality of the

supplied

water and the change in fluid speed.

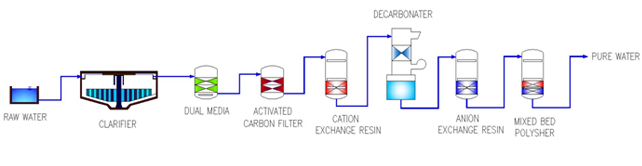

This device eliminates the cations by passing the supplied water through strong

acid cation exchange resin and then eliminates the anions by passing it through

strong alkaline anion exchange resin. In addition, the degasifier installed in the front

area of the anion exchange tower removes CO2. In this way, the amount of anion is

successfully reduced prior to entry to the anion exchange tower. Therefore, it is

desirable to reduce the consumption of NaOH, regenerative agent by reducing the

size of the anion exchange tower.