This system is to supply cooling water to heat loading systems, such as steel

manufacturing and power generating facilities. Using the technologies of precipitation,

filtering, isolation, and cooling, it cools down hot water and re- circulates.

Open and closed circuit types are available

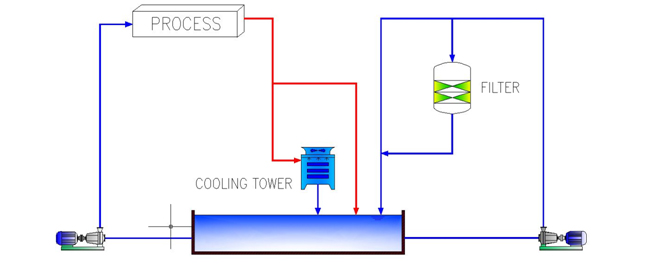

1. THE HOT WATER GENERATED IN THE PROCESS IS COOLED IN

THE COOLING TOWER BY INDIRECT HEAT EXCHANGE METHOD.

2. BY FILTERING 10~20% OF THE CIRCULATION WATER TO PROTECT

THE EQUIPMENT.

3. THE CHEMICAL DOSING EQUIPMENT IS TO PROTECT

TO THE

EQUIPMENT FROM CORROSION, SCALE & SLIM.

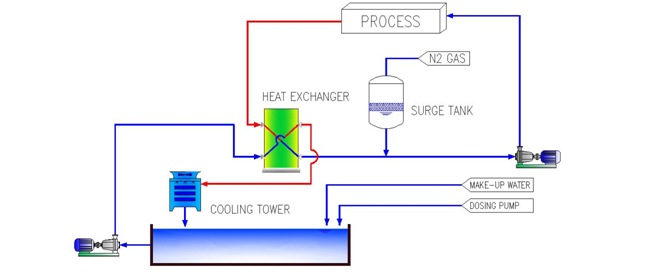

1. THE COOLING WATER REQUIRED FOR THE PROCESS IS

SUPPLIED BY THE HEAT EXCHANGER IN THE CLOSED SYSTEM.

2. THE COOLING TOWER REQUIRED TO COOL THE HOT WATER GENERATED

IN THE HEAT EXCHANGER. THIS IS OPEN SYSTEM.

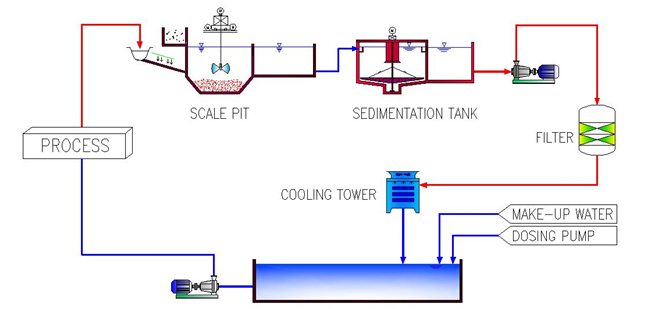

1. THE COOLING WATER IS DIRECTLY SUPPLIED

TO THE HEAT PLACE.

2. THE SYSTEM IS REQURED VARIOUS EUQIPEMT

(SEDIMENTATION, FILTERATION, CHEMICAL DOSING)

WHICH ARE TO REMOVE POLLUTION AS OIL,

SCALE & etc.

It precipitates, separates, and removes floats and suspended solids

included into the industrial water that is generated from industrial processes.

It precipitates, separates, and removes floats and suspended solids

included into the industrial water that is generated from industrial processes.

It secondarily treats the process water that is primarily precipitated and

separated in the scale pit. It filters minute floats and suspended solids.