This system is for harmful waste water coming from industrial jobsites of dyeing, plating,

and leather. It physically, chemically, and biological ly treats pollutants, such as

organic/inorganic matters and heavy metals. Organically using the nitrogen removal

technique, it fundamenta lly blocks the discharge of pollutants.

It is a pre-process for inorganic or organic waste water. The condition of the pre-process determines the efficiency of the main process and it can even guarantee smooth operation and high durability of the system.

This method utilizes the standard and long-term activation sludge methods, the contact oxidation method and the continuous batch reaction method to process the organic material that is not eliminated by a chemical process.

In addition to the biological processing, the chemical and electrical processes are used to process nitrogen and phosphorous.

The waste water recycling system that is currently recommended is a necessary system to save the scarce water resource and prevent environmental pollution

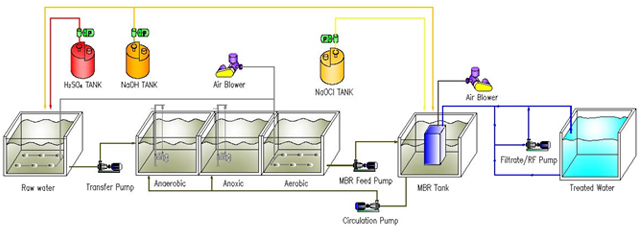

As MBR system is up-to-date combination of technology

waste water treatment technology, it is combined with

the bioreactor and separation membrane to the one

process and filter solidliquid separation process with

microorganism treatment to the separation membrane

within the aeration tank.

The capacity clearing T-N, T-P, particulates is excellent

and it is able to keep the high concentrations of MLSS

within the reactor. Also it doesnвҖҷt need a settling tank

facility so it can make the usability of the land.

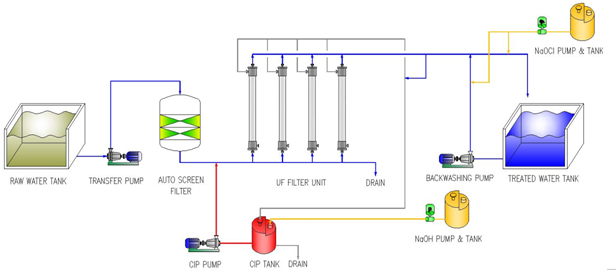

Extracorporeal ultra filtration using membrane of less

than 0.1Ојm pass water and eliminate germ, protein,

a high molecular substance or colloid particle.

Water treatment, industrial waste water treatment,

preprocessing В· post-processing, etc it is used in various

water treatment field.

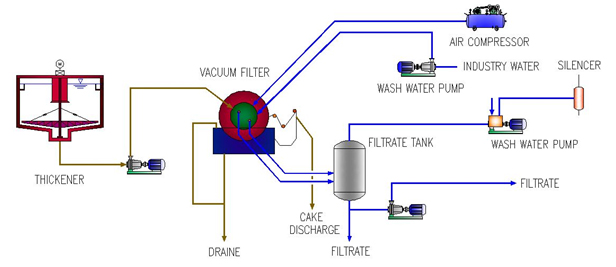

As a rotating drum filter that will perform continuous

filter in industrial wastewater, filter cloth or diatomite is

enveloped in a drum surface and it is a device that

separates the liquid and solid of wastewater inside the

drum working vacuum. And then adsorption, washing,

dehydration, desquamation are conducted in the detailed

process.

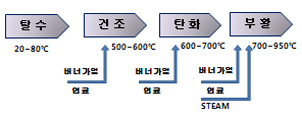

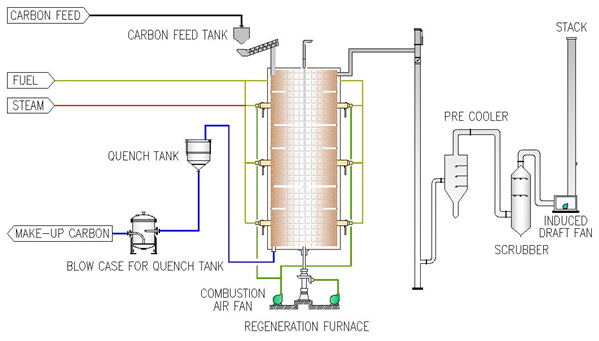

By reusing the saturated activated carbon that lose

adsorption capability, secondary prevention of pollution

caused by reclamation of waste, and activated carbon

recycling facility for savings waste water treatment costs

As activated carbon regenerative furnace is the facility

for restoring the original absorption ability of activated

Carbon after removing spent carbon inside the pole

water, organic matter, etc. processing the dry,

carbonization, revival process, it consists of a

regenerative furnace and supplementary installation.

It chemically treats polluted water, naturally precipitates,and isolates.

These days, a high-speed condens ation and precipitation apparatus is

used that each work of mixing, condensation, and precipitation is performed

in a sedimentation tank.

It makes microorganisms purify water through oxidation,

which uses activated sludge process, and through digestion by aerobic bacteria.

It reduces the percentage of water content of the sludge which is generated

in the process of treat ment, and increases the concentra tion of suspended solids.

Through this, it reduces the volume of raw sludge and at the same time,

it makes it harmless. This is for the safe and prompt treatment of sludge.

It evenly mixes sludge which comes from industrial jobsites with polymer and then,

discharges out sludge floc in the form of plate shaped-cake through a dehydrator.

It is a dehy drating system that consecutively treats large quantity.