| Item | CROSS FLOW TYPE |

|---|---|

| Exchange Type | ←Water ↓Air, Cross flow type |

| Efficiency | When the amount of water is equal to the heat exchange coefficient, its volume is greater than that of the counter flow type and theoretical interpretation tends to be more difficult. |

| Distribution of air stream | Since the louvers are located on both sides, as the tower height increases, the fan is further away from the air inlet. Therefore, dead space is generated in the heat exchange areas. |

| Water spray device | The hot water tank and the nozzle are exposed to the outside. So, it is easy to perform repairs and maintenance. In case of poor water quality, the system is still operable. |

| Power | The fan generates vertical air flows. So, less obstacles exist and the static pressure loss is low. You can use a lower power motor and save power consumption. |

| Water spray pressure | Gravity is used to spray water. So the water spray pressure is relatively low. |

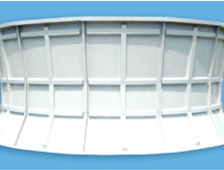

| Tower height | The

LOUVER, the FILLER and the ELIMINATOR are located

on the same horizontal line. Thus, the tower height is low. The filler height is equivalent to the tower height and the driving power of the pump tends to be small. |

| Area size of the tower | The

LOUVER, the FILLER and the ELIMINATOR are located

on the same horizontal line, so the area size tends to be large. If you add a ventilator, it tends to be even larger. |

| Temperature of the cold water tank | The temperature is not constant through the entire areas of the tank. The temperature at the edge of the tank is lower than the middle area. |

| Recirculation of the discharged air | The fan’s outlet is closely located to the louver, it is highly likely to recirculate hot and humid air that was already discharged. |

| Noise | Since the tower is not too tall and there is almost no separation between the filler and the cold water tank, it generates less noise. |

| Repair and maintenance | You can enter the tower through the entrance located in the middle of the tower. You can inspect the tower in operation and partial repair and maintenance is easy to achieve. |

| Price | A mid- or small-size is same as a counter flow type. If a large size is used, it will cost more than a counter flow type. |

| Item | Comparison of materials(STANDARD MATTERIALS USED) |

| FILLER

& ELIMINATOR |

DOUGLAS, FIR, PP, PS, PVC |

| FRA ME | DOUGLAS FIR, SS400+HDG, RF CON'C, FRP, SUS304 |

| FAN STACK | DOUGLAS FIR, SS400+EPOXY, SS400+HDG, RF CON'C, FRP, SUS304 |

| CASING & LOUVER | DOUGLAS FIR, CACB, RF CON'C, FRP |

| FAN DECK | DOUGLAS FIR, FRP, RF CON'C, SS400+HDG, SUS304, SS400+EPOXY |

| HOT WATER BASIN | DOUGLAS FIR, FRP, RF CON'C, SS400+HDG, SUS304, SS400+EPOXY |

| COLD WATER BASIN | FRP, RF CON'C, SS400+HDG, SUS304, SS400+EPOXY |

The kinds of frame are metal, RF CON' C and DOUGLAS FIR, Which is Treated to preserve from decay with ACQ and all metal frames are coated with zinc alloy and casing is composed of zinc coated plate or CACB combinated with FRP These features will give you high resistance of corrosion and guarantee high durability.

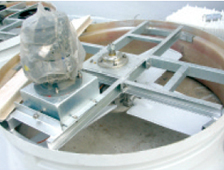

Prefabricated construction will be the most convenient to main tain the system.

Excellent eliminator will prevent from any water drift loss.

Newly developed V-belt double reducer or geared double reducer and FRP fan will give you low noise operation.

Utilizing rectification system increases the efficiency of filling and also prevents any water scattering to the outside of tower.

Low pressure in upper water tank(piping) gives excellent distribution of water spraying.

Big sized cold water basin equipped with drain and filing system will prevent any air inflow in pipe lines.

Specially designed 'Dae Hwa Tech Co., Ltd' bell mouth type FRP cylinder guarantees high preformance.

| MODEL / ITEM | SPECIFICATION | DIMENSION | CELL | FAN & MOTOR | |||||

|---|---|---|---|---|---|---|---|---|---|

| R/T | AIR VOLUME (cmm) |

WATER FLOW (㎥/hr) |

W | L | H | EA | DIA(Φ) | KW | |

| DHG-CU-600 | 600 | 3,978 | 468 | 6,200 | 9,600 | 3,600 | 2 | 2,400 | 75x2 |

| DHG-CU-700 | 700 | 4,641 | 546 | 6,200 | 9,600 | 4,100 | 2 | 2,400 | 11x2 |

| DHG-CU-800 | 800 | 5,304 | 624 | 6,200 | 9,600 | 4,600 | 2 | 2,400 | 11x2 |

| DHG-CU-900 | 900 | 5,967 | 702 | 7,400 | 12,000 | 3,400 | 2 | 3,000 | 11x2 |

| DHG-CU-1000 | 1,000 | 6,630 | 780 | 7,400 | 12,000 | 3,800 | 2 | 3,000 | 11x2 |

| DHG-CU-2000 | 2,000 | 17,000 | 1,560 | 8,700 | 11,000 | 4,500 | 2 | 3,600 | 45x2 |

| DHG-CU-3000 | 3,000 | 25,500 | 2,340 | 8,700 | 16,500 | 4,500 | 3 | 3,600 | 45x3 |

| DHG-CU-3800 | 3,800 | 37,800 | 2,964 | 10,250 | 21,800 | 5,200 | 3 | 4,800 | 45x3 |

※ This SPEC according to situation could be changed, with our company discussing.

The motor of the cooling tower is totally closed and designed to make high efficiency. Based on customers' requirement, a pole change type or an inverter type is supplied. The reducer and the shaft are designed suitably for the horse power and the RPM of fan speed. It is special waterproof-treated so it can stand long-item consecutive driving under high temperature and humidity

The V-belt reducer for the cooling tow er is used for less than∮3,600 fan clia meter and low hp. it's menufacture and installation are simple, and it is easy to repair and maintain.

It has nead appearance and close blade tip clearance, through which it improves the performance of the cooling tower. ∮1,200 ~ 10,000 are available and it is made of FRP, steel plate, or wood.

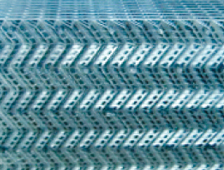

Eliminator, which prevents the loss of water caused by scattering and evaporation, is made of PP, PVC, HIPS, or wood, Depending on the type of the cooling tower, other material, which is excelent at heat resistance and acidity removal and has long ifetime, can be used.

The filler makes the heat transter area of water and air and the heat exchange time large. A splash type and a film type are avalable. Wood, PP, PVC, or HIPS, which is heat-resistant enough to stand hot water, is used.

It is designed to determine the direction of air flow and to increase the cooling effect. FRP or aluminum is used.

| NUMER | MODEL NAME | SIZE | MATERIAL | Max Temperature | REMARK |

|---|---|---|---|---|---|

| 1 | DHG-100 | 1500LX730WX340H | P.V.C | 85℃ | design reg no.0262285 |

| DHG-100-1 | 1500LX740WX340H | P.V.C | 85℃ | ||

| 2 | DHG-101 | 1800X350WX340H | P.V.C | 85℃ | |

| 3 | DHG-200 | 1600LX780WX340H | P.V.C | 85℃ | |

| 4 | DHG-300 | 1700LX765WX340H | P.V.C | 85℃ | |

| 5 | DHG-400 | 1625LX750WX340H | P.V.C | 85℃ | |

| DHG-400-1 | 2000LX650WX340H | P.V.C | 85℃ | ||

| 6 | DHG-500 | 1625LX450WX340H | P.V.C | 85℃ | |

| DHG-500-1 | 2000LX420WX340H | P.V.C | 85℃ | ||

| 7 | DHG-600 | 1800LX750WX340H | P.V.C | 85℃ | |

| DHG-600-1 | 2000LX650WX340H | P.V.C | 85℃ | ||

| 8 | DHG-601 | 2000LX680WX340H | P.V.C | 85℃ | |

| DHG-601-1 | 1800LX800WX340H | P.V.C | 85℃ |

The DHG TYPE P.V.C. FILTEER ELEMENT is a heat-resistant product. Unlike general material, it offers great heat resistivity of 85℃ and is also highly durable. it is a standard product with multi-purposes applicable to any type of cooling tower.