| NO | PART NAME | MATERIAL |

|---|---|---|

| 1 | MOTOR | TEFC |

| 2 | V-BELT | RUBBER |

| 3 | MOTOR SUPPORT | SS400+HDG |

| 4 | HOUSING | GC |

| 5 | FAN BLADE | FRP |

| 6 | FAN STACK | FRP |

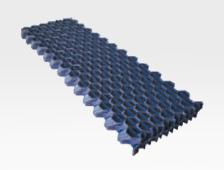

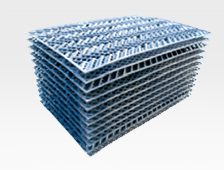

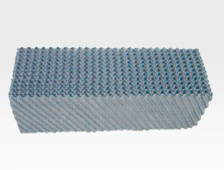

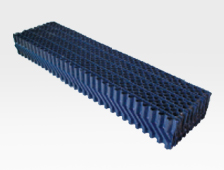

| 7 | ELIMINATOR | PVC |

| 8 | DISTRIBUTION PIPE | PVC / PE |

| 9 | NOZZLE | PP |

| 10 | FILLER | PVC |

| 11 | FILLER SUPPORT | SS400+HDG |

| 12 | CASING(BODY) | FRP |

| 13 | LOUVER | EX / METAL or PVE |

| 14 | COLD WATER BASIN | FRP |

The weak point which the cooling water leaned to one side is removed by the air velocity which is sucked and the head exchange efficiency is maximized. The interval maintenance method of filler was especially designed and the air resistant minimized.

We improved the efficiency of heat exchange by jetting out the cooling water sufficiently through the SPRIAL TARGET NOZZLE and the DISTRIBUTION EQUIPMENT which is added at the top of the filler.

The width of filler was made longer.

Optimum arrangement in fan and filler removed DEAD SPACE of air flow and promoted the efficiency.